The Zklysen Organic Solvent Recovery Technology and Industrial Energy-saving Distillation Laboratory is capable of conducting various distillation and extraction experiments, and is equipped with complete distillation and analysis experimental equipment. It has various professional technical personnel, covering process research and development, process package design and experimental method design. So far, it has developed nearly two hundred solvent recovery methods for various systems, including the separation of salt-containing and tar-containing systems.

By utilizing the difference in volatility of each component in a liquid mixture, the liquid mixture is partially vaporized and the vapor is partially condensed, thereby achieving the separation of its components

Separation is achieved by utilizing the difference in solubility of each component in a liquid mixture in a certain solvent, that is, by blending a solution with another immiscible liquid with a higher affinity for impurities to separate a certain component

A separation method combining thermally driven distillation and membrane method: a liquid (or vapor) mixture is driven by the vapor pressure difference of its components, and the process of separating substances is achieved by utilizing the different adsorption and diffusion rates of the components through a pervaporation molecular sieve membrane

The simplest recycling technology is to cool the exhaust gas to a temperature lower than the dew point temperature of organic matter, condense the organic matter in the exhaust gas into liquid form, and then directly separate it from the exhaust gas to achieve effective recycling.

According to the principle of similar solubility, the solvent air mixture is introduced into the equipment from the bottom and absorbed and dissolved by an oily liquid with a boiling point and low viscosity that is sprayed from the top

The main method is to use granular activated carbon, activated carbon fibers, and zeolites as adsorbents to adsorb and treat organic solvents. When the exhaust gas passes through the adsorption bed, the organic matter will be adsorbed by the adsorbent in the bed layer, thus purifying the exhaust gas.

Strong team of experts

Strong team of experts

A doctoral team with rich experience in large chemical and pharmaceutical enterprises

Systematic solutions

Systematic solutions

Having multiple exclusive process packages, we can undertake chemical and pharmaceutical engineering consulting, existing chemical equipment technology transformation, and operation services

Professional experimental platform

Professional experimental platform

Subcritical catalytic oxidation experimental center and organic solution recovery and industrial energy-saving experimental and pilot platform

Efficient on-site service

Efficient on-site service

Having skilled and experienced debugging and operation service personnel, providing fast and professional on-site services;

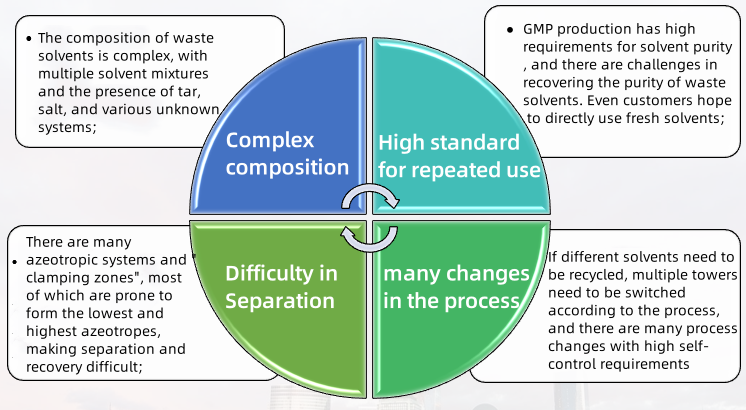

Fine chemical production is mostly an organic reaction, which uses organic solvents as reaction carriers. During the production process, a large amount of complex waste solvents are inevitably generated. Realizing the recycling and utilization of waste solvents is the key to reducing costs and increasing efficiency in fine chemical enterprises, and is the guardian of "green mountains and clear waters".

Zklysen's organic solvent recovery technology and industrial energy-saving distillation laboratory have the ability to carry out various distillation and extraction experiments, equipped with complete distillation and analysis experimental equipment. We have various professional and technical personnel, covering process research and development, process package design, and experimental method design. Currently, nearly 200 solvent recovery methods have been developed, including the separation of salt and tar containing systems.

Difficulties in solvent recovery

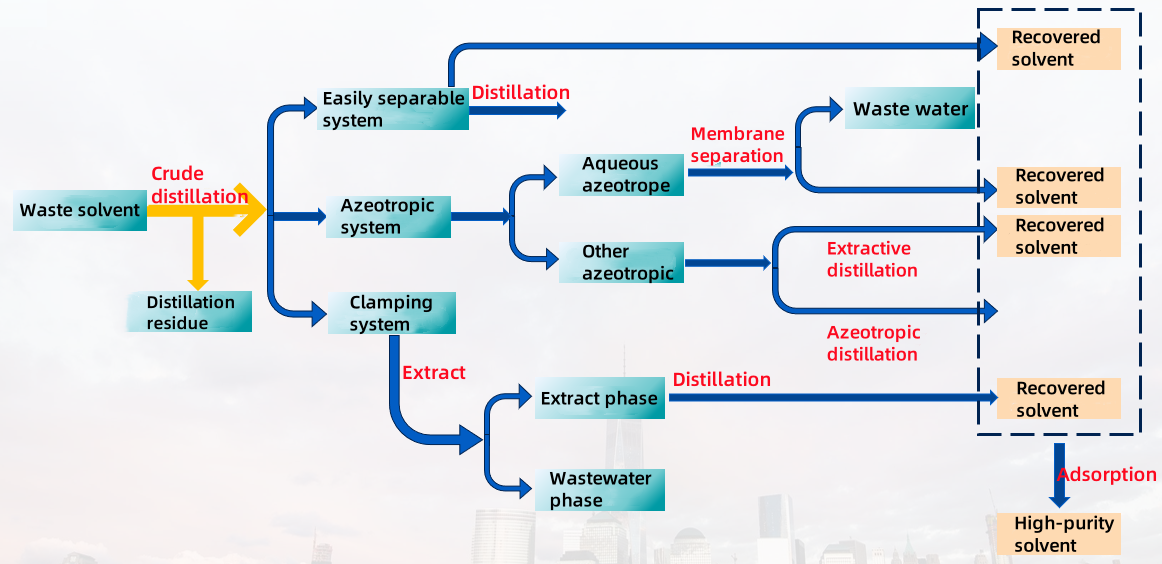

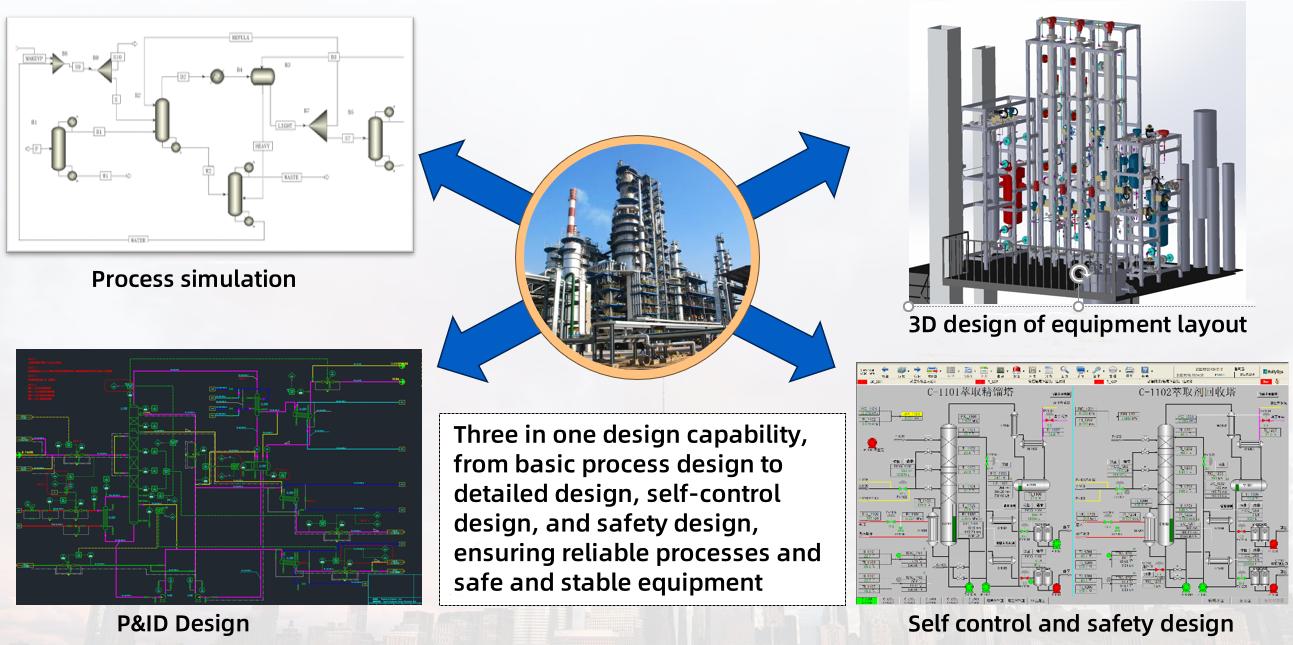

Zklysen Complex Solvent Separation and Recovery Technology - Engineering Scale Design

Design of Separation Process Route

Specific problem analysis, customized process recycling routes suitable for each enterprise

Submit your information and we will contact you as soon as possible